Commonly Use Flexible PCBs

PCBs are the heart of most electronic devices and hardware. Whether they are designed for use in home or office devices, consumer electronics like digital cameras, cell phones or wearable gadgets such as activity trackers, flexible printed circuit boards are becoming increasingly popular. In fact, the flexibility of these circuits is driving innovation in several industries.

In this article, we will explore some of the most common applications for flex PCBs and why they are ideal for those applications. For starters, flex circuits are lightweight and compact, which makes them well-suited for portable and mobile devices. In addition, these circuits can endure harsh environmental conditions such as extreme heat and cold, as well as moisture.

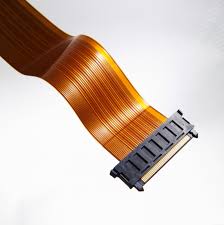

A typical flexible PCB consists of a conductive copper layer that is laminated onto a malleable base material such as Polyimide. Conductive lines or traces are then etched on the surface of the base material, and the whole assembly is covered with a coverlay film that works to protect the copper from contamination. Finally, the entire flexible pcb is then rolled into a tube for transport and storage purposes.

The primary benefit of flex PCBs is their flexibility. This allows them to fold, crease and bend into the shape of the device or product that they will be part of. This is important for many applications because it eliminates the need for manufacturers to build an entire device or case around the circuit board. This design flexibility also allows flex circuits to take on irregular shapes, which is helpful in some situations such as the electronics found in vehicles.

What Industries Commonly Use Flexible PCBs?

Lastly, flex circuits can handle vibrations and shocks much better than rigid PCBs. This is because they are able to bend and flex, which helps absorb the impact of these forces. Rigid PCBs, on the other hand, are more likely to warp or even break under these kinds of conditions.

Other industries that commonly use flex circuits include computer equipment such as printers, gaming systems and microwaves, as well as hard drives for portable devices like MP3 players and mobile phones. In these applications, flex circuits are primarily used to increase speed and performance and allow the device or product to remain small and lightweight.

Finally, flex circuits are used extensively in the automotive industry to help with a wide range of tasks. From engine management units (EMUs) to anti-lock braking systems, airbag controllers and instrument panels and dash systems, flex circuits are an essential component of modern vehicle technology. They also offer designers significant amounts of flexibility, allowing them to create more compact designs and to easily sync up electronics without the need for bulky wires or cable ties.

In the healthcare sector, flexible PCBs play a crucial role in various medical devices. They are used in devices such as pacemakers, defibrillators, medical imaging equipment, and wearable health monitors. Their flexibility allows for integration into curved or irregularly shaped devices while maintaining reliability and performance.

Modern vehicles incorporate an increasing number of electronic components, and flexible PCBs are integral to this trend. They are employed in automotive infotainment systems, GPS navigation, engine control units (ECUs), and advanced driver assistance systems (ADAS). Their flexibility enables efficient routing of wires in tight spaces within the vehicle’s interior.